This project involved the creation of a 3-D printed ocular model, to teach capsulorrhexis formation in cataract surgery.

A crucial step of cataract surgery involves the creation of a hole in the anterior capsule of the lens complex; this step is a termed “creating a continuous curvilinear capsulorrhexis (CCC)â€. Current methods of teaching this step of surgery involves using artificial eyes, porcine eyes, or simulators. However, these methods are either costly or suboptimal due to media opacity.Â

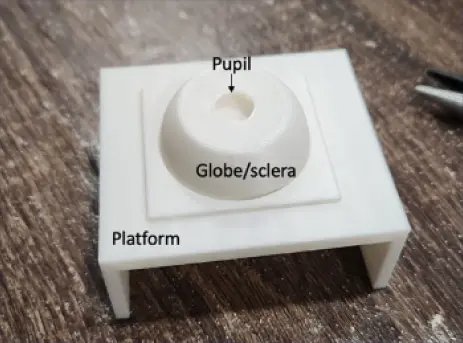

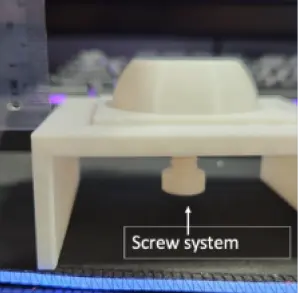

This project involves the design and creation of a 3-D printed ocular model, which acts to secure a small thin-skinned fruit (e.g. tomato or grape) in an anatomically accurate position. The 3-D printed ocular model includes the creation of a mount attached to a screw system that holds the fruit behind an artificial plastic iris and within a mydriatic plastic pupil. A transparent cornea has also been created with an aperture mimicking the main-port wound used during cataract surgery to allow intraocular access. Through this aperture, the trainee can learn how to initiate, continue, and complete a CCC in a safe and progressive manner. We hope this project will result in improved surgical technique, resulting in fewer complications during cataract surgery.

(i) Side profile of screw system

(ii) Screw loosened

(ii) Screw tightened

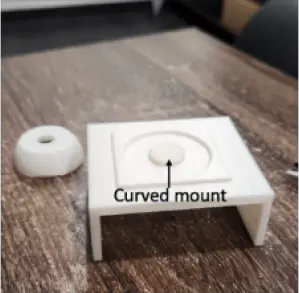

Curved mount to hold grape attached to a screw system to hold the grape via tension between the platform and posterior surface of the plastic iris.

(i) Side profile of screw system

(ii) Screw loosened

This project has been awarded the Ng Teng Fong Healthcare Innovation Programme Grant. Residents at the beginning stages of cataract surgery training will be undergoing a structured programme of training with the model, with analysis of surgical confidence and self-efficacy scales.